The smart appliance brand RedRoad sees product quality as its lifeline. RedRoad works with suppliers who use strict quality control to protect the interest of its consumers, starting with raw materials with the highest industry standards.

Strict quality control: RedRoad sees product quality as a lifeline

RedRoad has in fact created a highly efficient quality and safety control system, has invested millions of dollars to build an electrical device test center that meets the criteria of ISO, IEC 17025: 2005. General criteria for the competence of testing and calibration laboratories.

RedRoad has established a supplier quality management team, which manages more than 200 suppliers. Team members have excellent professional skills and higher quality control standards than their peers. If a component manufacturer wants to become a RedRoad supplier, they have to go through rigorous qualification checks. In addition to passing various international certifications, the products must pass inspections before they can enter the RedRoad shopping list.

If we take a vacuum cleaner as an example, RedRoad's cable fatigue tester uses a robot to simulate a human hand to bend the wire. The wire is considered suitable only after 2 weeks, 600.000 times of gripping and bending without breaking. Most companies of the same type only score 450.000 times, so RedRoad ranks over 25% higher than peers. The same applies to all other components of the vacuum cleaner which will also be subjected to a fatigue test.

After becoming a supplier, each batch of products supplied for RedRoad still has to go through a rigorous screening process, the unsuitable products will be placed in a special red box for unwrapping. If the rate of return is below the standard, the entire batch will be returned to the factory. According to the requirements of this system, the supplier must use the most sophisticated technology for the products for RedRoad.

It is almost impossible for unsuitable parts to enter the assembly line. However, in order to improve the quality, the RedRoad production line has set up a reward mechanism, front line workers will supervise the quality of parts and other minor design problems. Assemblers who discover any problems will immediately set off an alarm on the production line. After verification, if it is indeed a problem, the worker will be rewarded.

The RedRoad Quality Inspection Center, which cost millions of dollars, has achieved world-class certification. Its quality inspection level has reached the world-recognized level of management and testing capabilities, and its test results can be recognized by more than 20 countries and regions around the world.

The control procedures include noise tests, water resistance, bending of various parts, the life of the whole machine, etc. Each process has a strict standard control, such as the carpet cleaning test. The tested carpet must be “housed” in an air-conditioned room at constant temperature and humidity for 24 hours in advance, and the test can only be carried out by ensuring the stability of the various performances. Let's take another example: for any new product, the first batch will be sent to the test platform to simulate the conditions of use in working tests in all weather conditions.

In order to guarantee a worldwide shipment with which the vacuum cleaners in the package have no problems during cross-border transport, the RedRoad Testing Center has chosen a package with constant temperature and humidity. He also simulated the transport, placing the package from the vacuum cleaner in a container which is heated to a temperature of 70 degrees Celsius for 45 days. Once the test is finished, you go to check that the package is not damp or deformed, the label of the box is still in good shape, and the vacuum cleaner itself has no problems in appearance or quality. Only in that case will it finally be judged as a suitable product.

The high quality of the product is the preservation of the value paid by the users. Without quality, no matter how good a product's performance or features are, it is not possible to guarantee the same experience for all users.

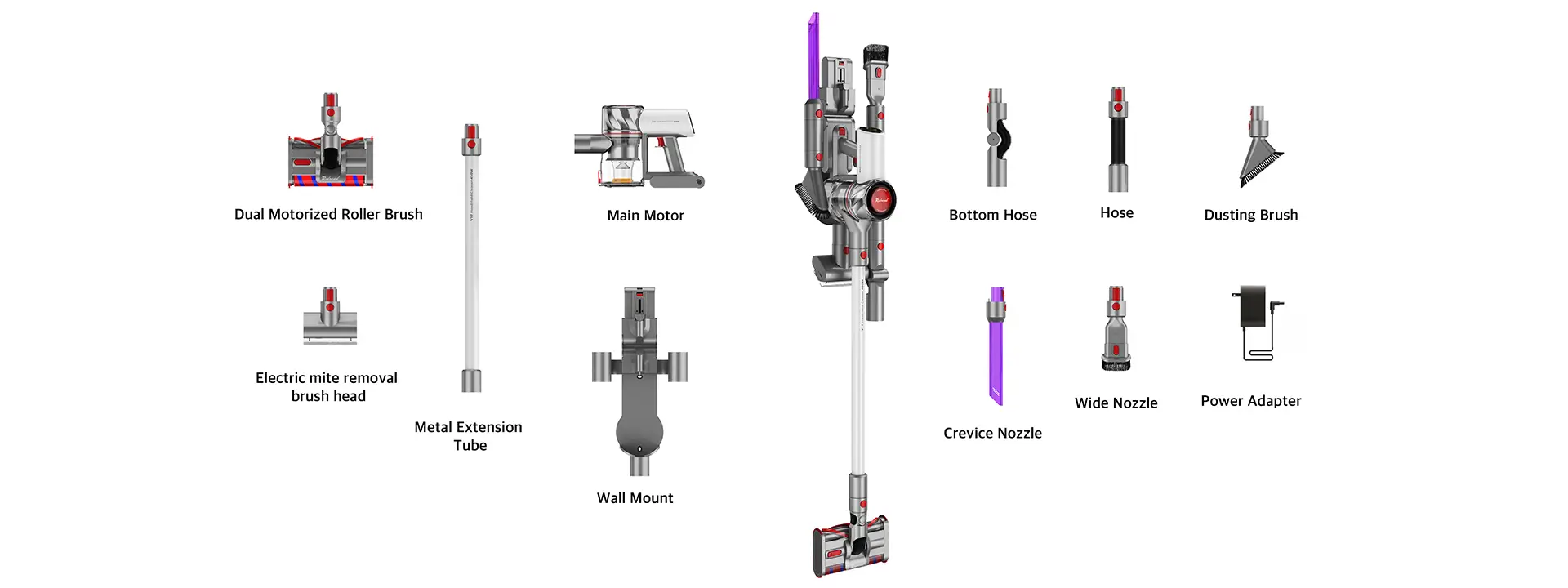

Of course, the upcoming RedRoad V17 Handheld Cordless Vacuum Cleaner, which will be released in September, has also passed a rigorous quality check.

For more info on RedRoad V17 and other RedRoad products you can visit the Official site.